Wrapped bronze bearings

Long service intervals under severe operating circumstances.

Wrapped bronze bearings are ideal for applications where there are high levels of contamination. Their running surface is provided with diamond-shaped lubrication pockets or a hole pattern. The lubrication pockets must be filled with grease when the bearing is installed. The wrapped bronze bearings are produced according to the ISO 3547.

Advantages of wrapped bronze bearings

The main advantages of wrapped bronze bearings include:

- Long service intervals

- Not affected by impurities

- Suitable for corrosive environments

- Suitable for impact loads and vibrations at low speeds

- Good heat dissipation

Applications of wrapped bronze bearings

Wrapped bronze bearings are especially suited to severe operating conditions where frequent maintenance is not possible. Common applications are:

- Agricultural vehicles

- Lifting gear

- Offshore

- Excavators

Materials

Wrapped bronze bearings are made entirely from phosphor bronze CuSn8. CuSn8 is characterized by the purity of the alloy with only a very low level of impurities. Wrapped bronze bearings are produced from strips that are subsequently wrapped and calibrated.

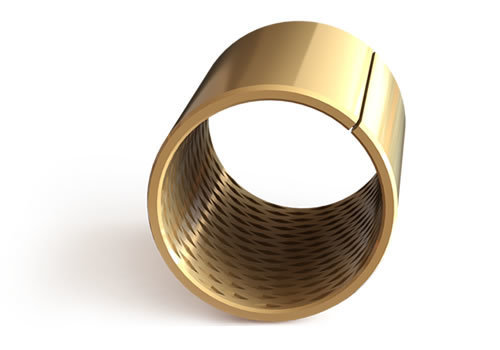

Lubrication

Wrapped bronze bearings must be lubricated with grease or oil on installation. A good quality lubricant is essential as it will reduce friction and wear by forming a film between the plain bearing and the shaft. For heavily contaminated applications, we recommend sealing off the bearing. This will protect both the bearing and the lubricant.

Detail overview of lubrication pockets

Specification overview of wrapped bronze bearings

| Specification overview | ||

|---|---|---|

| Properties | T90 | T92 |

| Max. load (Dyn/stat), N/mm2 | 40 / 120 | 40 / 120 |

| Max. sliding speed m/s | 2.0 | 2.5 |

| Max. PV value N/mm2 x m/s | 2.8 | 2.8 |

| Temperature range, oC | -100 / +200 | -100 / +200 |

| Shaft tolerance | e7 - f8 - h6 | e7 - f8 - h6 |

| Housing tolerance | H7 | H7 |

| Shaft roughness | Ra ≤ 0.8 | Ra ≤ 0.8 |

| Shaft hardness | > 200 HB | > 200 HB |

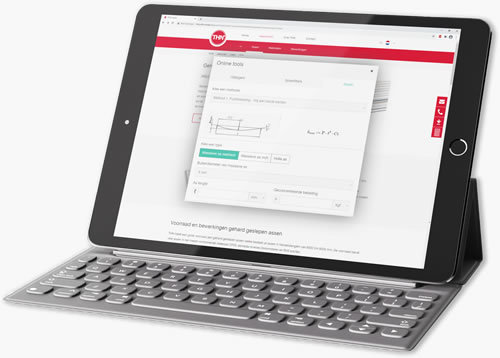

Product finder plain bearings

Find the right plain bearings for your applications with the online product finder. Enter the values for the load, speed, inner diameter and length. You immediately get an overview of the type of plain bearings that match the entered values. This way you know exactly which plain bearings are most suitable for your application.

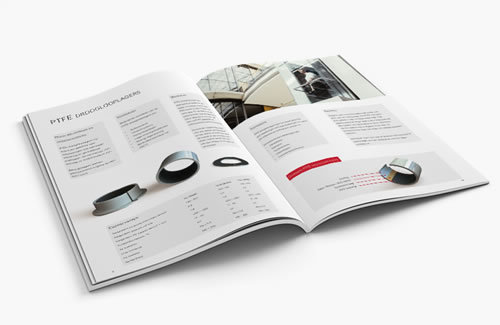

Download plain bearing brochure

Download the brochure in which you can read everything about our range of plain bearings. It contains a plain bearing overview, a specification overview and more information about materials and lubrication. Of course you will also find the complete size lists in the brochure.

Download brochureNeed technical advice?

Are you looking for plain bearings and do you want to contact a technical advisor? Call us on +31 (0)53 - 432 34 46 or send an email to info@thn.nl. We are happy to help.

Contact us